PCHEM strives to offer an extensive selection of high-quality products designed for moving industrial liquids. We focus on direct production for specific product lines, while establishing strong partnerships with leading manufacturers for other ranges.

Our diverse solutions cater to the unique needs of various application sectors, ensuring optimal performance in fluid movement. PCHEM's products and solutions span across multiple industries, offering tailored options to address the distinct requirements of each sector. Dive into our offerings and discover the perfect solution for your industrial fluid movement needs.

Magnetic drive pumps are becoming the standard in installations handling aggressive or potentially dangerous liquids. According to their size, performance and type of pumped liquid, they can be made entirely of technopolymers or can have a metal structure with coatings resistant to aggressive liquids. In all cases, they are characterised by the fact that all static and rotating parts in contact with the fluid are contained within a perfectly sealed body. The motor transmits motion to the pump impeller through a MAGNETIC COUPLING so that there is no need for a connecting shaft and associated rotary seals.

DDC pumps are made entirely of TECHNOPOLYMERS resistant to chemically aggressive fluids. They are characterized by a HERMETIC SEAL that eliminates the risk of leakage, a common weakness of pumps with rotary seals. Powered by low-voltage direct current, they are equipped with control electronics for controlling pump performance and dialogue with the control electronics of the systems on which they are installed. They are particularly appreciated by OEMs because of their compactness, which allows them to be used in systems that need to handle low and medium-viscosity liquids.

DIAPHRAGM PUMPS solve many pumping problems deriving from the aggressiveness of pumped fluids and their physical characteristics. They are versatile and easy to adjust and use. The presence of only static seals and the special design of the valves allow them to be used for handling fluids with low and medium viscosity and/or containing solid parts. The series offered are all of the DOUBLE DIAPHRAGM types and are powered by compressed air, making them suitable for use in ATEX classified areas or where the compressed air supply is advantageous from a plant engineering point of view. The different series offered are united by the same robust construction but differ in terms of the materials of construction in contact with the fluid, available in a wide range of configurations for every need. The compressed air motors with which they are equipped to guarantee high reliability, long service life and low air consumption.

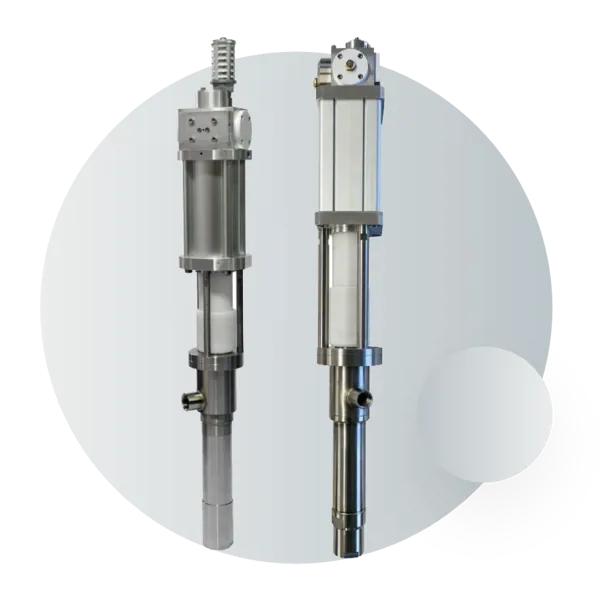

The PISTON PUMPS in this series are made of STAINLESS STEEL and are driven by compressed air. By exploiting the various available pressure ratios, they are particularly suitable for pumping even high-viscosity fluids or in systems with a high pressure drop. The absence of electrical parts makes them particularly suitable for ATEX classified areas or where the compressed air supply is advantageous from a plant engineering point of view.

All reciprocating pumps are inevitably characterized by a pulsating flow rate. Flow pulsations can cause problems and must be minimized in many applications. The PULSATION DAMPENERS in this series are patented and characterized by a PASSING FLOW construction and the presence of a DOUBLE DIAPHRAGM compensation to minimize pulsation.

Pneumatic diaphragm valves are ideal for ensuring reliability in the processing of aggressive fluids due to their simple, patented construction, easy maintenance and no sliding parts. Driven directly by compressed air, they are simple, cost-effective and quick to install. Large passages ensure a low pressure drop and minimise the need for cleaning.

Measuring the flow and volume of processed liquid, as well as checking the level in the tanks is often an essential condition for proper plant management. Doing this in presence of aggressive liquids is often difficult and expensive. The series of FLOW METERS and LEVEL INDICATORS solve many of these problems with interesting technical solutions adopted and a full available range.

We want your experience with Pchem to be in line with your needs. Please do not hesitate to contact us, our Customer Care team is available to assist you and answer any questions.

CHEMISTRY

CHEMISTRY

PHARMACEUTICALS

PHARMACEUTICALS

TANNERY

TANNERY

FOOD

FOOD  WATER

WATER  PAPER

PAPER  INDUSTRIAL

INDUSTRIAL